Hiland Tray

StratcoSKU: Hiland-Tray

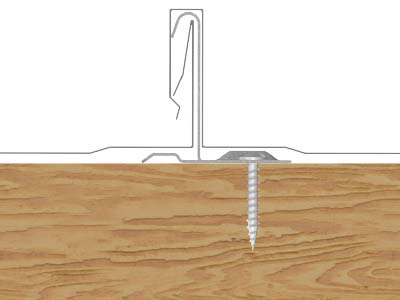

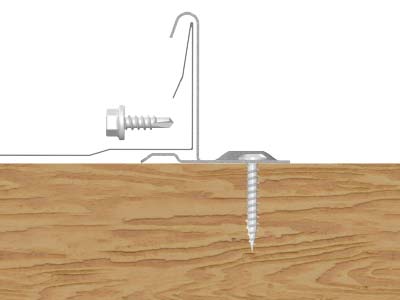

Hiland Tray is an innovative product that is available in long, single lengths. Hiland Tray is snap-locked to concealed fixings via a simple clip system that is attached to the roof and wall purlins.Image gallery

Versatile and Innovative Cladding

Snap-locked to concealed fixings

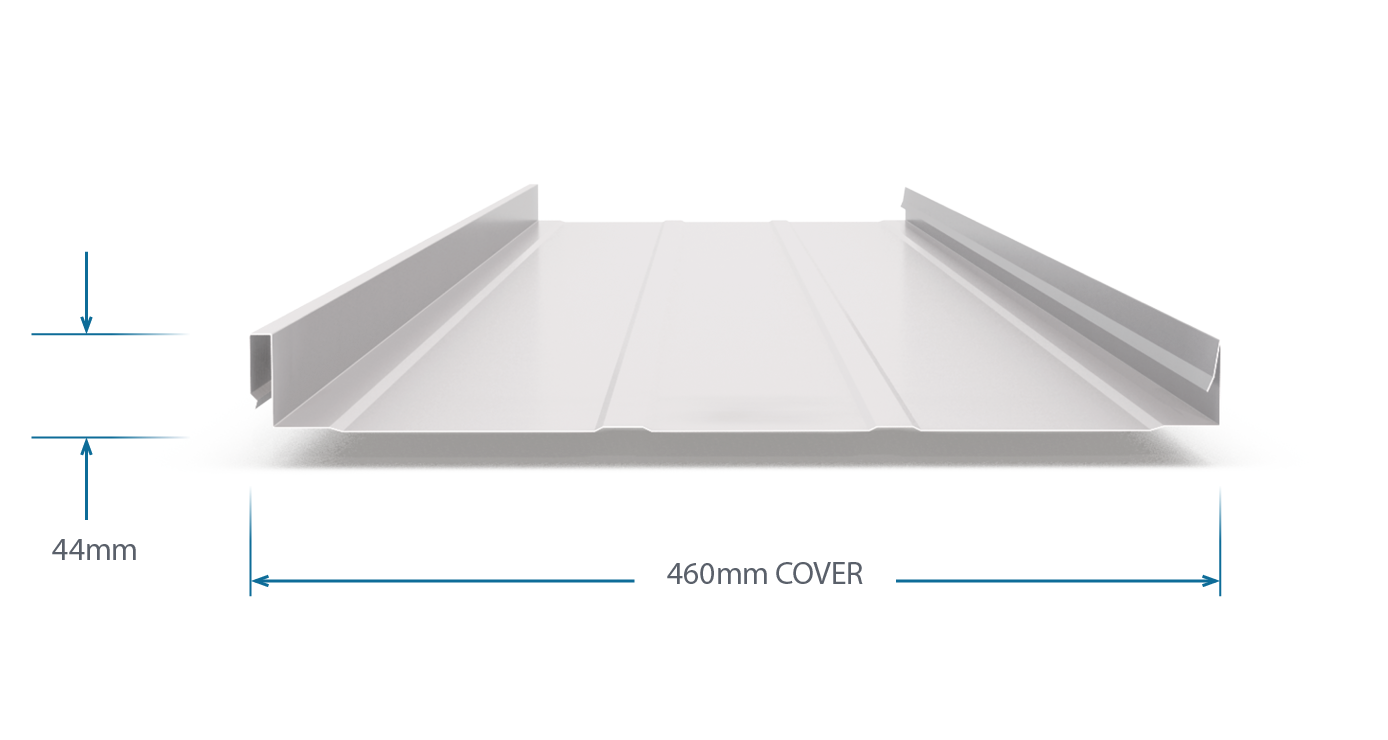

Hiland Tray is a proprietary 460mm wide tray roofing and wall cladding system, that does not require a supporting substrate in most applications and is secret fixed or ‘snap locked’ to roof purlins and wall girts using a concealed clip fixing system. With a rib height of 44mm, Hiland Tray provides greater water carrying capacity as well as strength for snow loading applications in alpine regions.

The profile is available with the option of swages within the tray pan, or no swages for a more traditional look. Regardless of the options chosen, the flat nature of the tray pan means that oil canning (wave or ripple) in the pan of the product can occur through thermal movement and is inherent in most wide, flat steel roofing and wall cladding products. This is an aesthetic issue only and does not affect the performance of the product and adds to the crafted and characteristic appearance of the product.

Hiland Tray is usually manufactured at a Stratco facility and delivered to site. For larger projects or where there are long lengths required, an option for manufacturing onsite with a mobile roll forming facility is also available.

Available in a range of colours:

Contact us for more information on the current colour range.

Brochures & Installation Guides

High Performance Cladding

The Hiland Tray profile has a high rib height of 44mm that enhances its smooth bold lines and provides greater water carrying capacity and strength for snow loading applications in alpine regions. Hiland Tray is available in 0.55mm BMT in a range of contemporary pre-painted colour steel options to suit any colour pallet.

Maintenance

The performance of Hiland Tray roofing and wall cladding over time depends on its correct application and maintenance. Maintenance should be performed as often as is required to remove any dirt, salt and pollutants.

Where Hiland Tray cladding is used in severly corrosive environments, cleaning should be performed more often. It is important that screws have the same life expectancy as the Hiland Tray cladding you have specified. Packs of Hiland sheeting should always be kept dry and stored above ground level on site. If the sheets have become wet, they should be separated, wiped and placed in the open to dry.

Refer to the Stratco 'Selection, Use and Maintenance' brochure for more detailed information about the correct use and maintenance of this product.

Material Specifications

| Material Specifications | ||

| Material Properties | Finish | 0.55 BMT |

|---|---|---|

| Minimum 'AZ' Coating Mass (g/m²) | Zinc/al & Colour | 150 |

| Mass (kg/linear metre) | Zinc/al | 2.71 |

| Colour | 2.75 | |

| Mass (kg/square metre) | Zinc/al | 5.97 |

| Colour | 6.05 | |

| Yield (square metre/tonne) | Zinc/al | 168 |

| Colour | 165 | |

| Tensile Strength (MPa) | Zinc/al & Colour | 340 |

| Width Coverage (mm) | Zinc/al & Colour | 460 |

| Sheet Tolerances (mm) | Length & Width | ±5 ±2 |

| Minimum Roof Pitch | Zinc/al & Colour | 3° |

Fixing Recommendations

Hiland Tray sheets should be laid into the prevailing wind and clip neatly onto the preceding roof sheet. The Hiland Tray clips should be fixed within the recommended support spacings.

Due to the seam height, flashing turn downs into the pan of Hiland Tray sheeting should always be notched around the rib to provide maximum weather tightness.

Laying Procedure

Laying Direction →

← Prevailing Wind

Installation Details

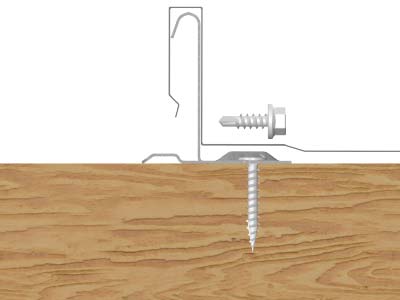

Concealed Clip Fixing

Fixing to Timber

Two 10 x 30mm wafer-head timber fixing screws (square drive recommended) per clip. Clips located at every sheet overlap and sheet edges at each timber support. Timber supports to be 70mm x 45mm SG8.

Walking on Hiland Tray

When walking on Hiland Tray roofing, walk over the purlins to avoid damage to the sheeting. Wear flat rubber soled shoes and walk flat footed in the pans only. Walking on end spans is restricted explicitly to over the end span purlins with no access allowed directly on end spans due to potential sheet damage.